Extension

Springs

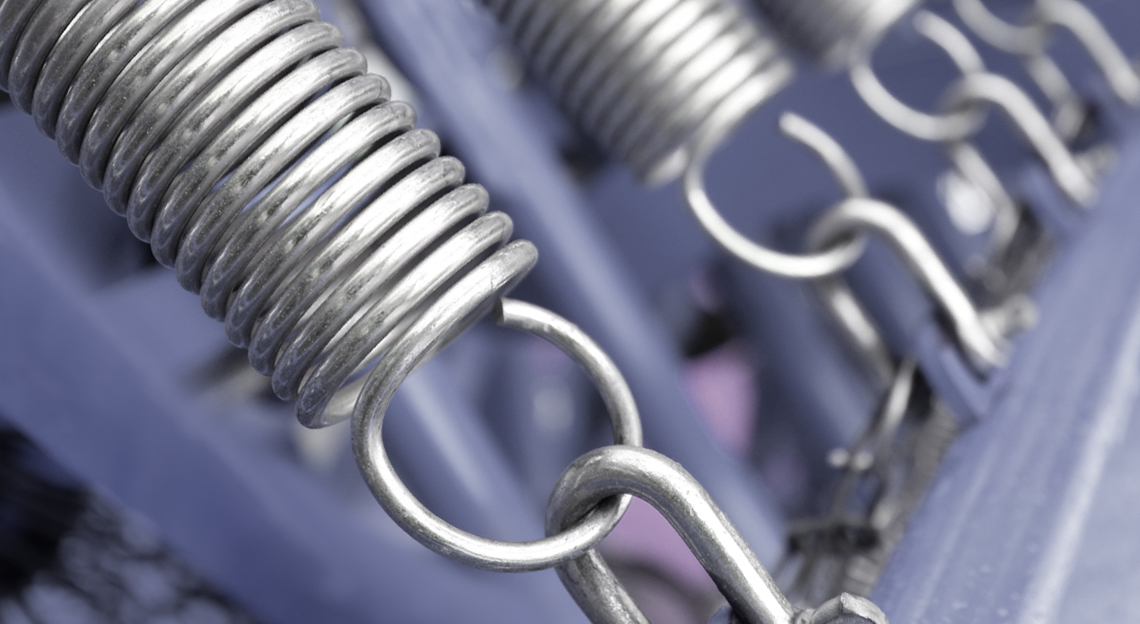

Extension springs have a wide range of applications and uses. They are close-coiled spring that are used where a force is required to pull between two points - the opposite of a compression spring, where the force is repulsive. As for compression springs, they are relatively easy to design and manufacture although the type of end hook or loop can be important. For more detailed information on extension springs contact our design department or consult EN13906-2: 2013

Extension springs can be made from round or square wire, although round is considerably cheaper and easier to manufacture. We keep a vast selection of material sizes and types in stock, from standard spring steels to nickel alloys, all of which can be used to manufacture extension springs.

When ordering an extension spring

consider the following factors:

Wire size

Specify either metric or Imperial measurements or Standard Wire Gauges. We stock all the standard wire sizes and also a large range of non-standard wire sizes for specific requirements.

Body Diameter

Specify the outside diameter of the main part of the spring, or the size of the hole it is to go into (if any). Usually, the diameter of the end loops or hooks is the same as that of the body of the spring but if not, specify their diameter too.

Number of coils

The number of active coils is inversely proportional to the rate (strength) of an extension spring. A large number of coils will result in a fairly weak spring. A small number of coils will give a relatively strong spring.

Length

Specify the free length of the spring - either the body length (BL), inside loop length (FL IL) or the free length overall.

Initial Tension

This is the force required to just open the coils of an extension spring. This property of the spring can be varied to a certain extent if required - contact our design department for more details.

Rate

The rate (strength) of the spring depends on the above factors and can easily be calculated. However, sometimes the rate is the starting point from which the design can be based. This is particularly useful if the forces required at particular working lengths are critical. Rate is defined as the force that has to be applied to the spring in order to produce a unit deflection and is measured in either Newtons per mm (N/mm) or pounds per inch (lb/in).

Hook / Loop types

The following are examples of end arrangements for extension springs:

Machine loop.

Crossover loop.

Extended round loop.

Coned end with swivel loop.

Plain-end spring with threaded insert.

The most common loops/hooks are the machine and crossover loop

More "exotic" loops or hooks are generally not used unless there is a specific reason for doing so.